Our Products

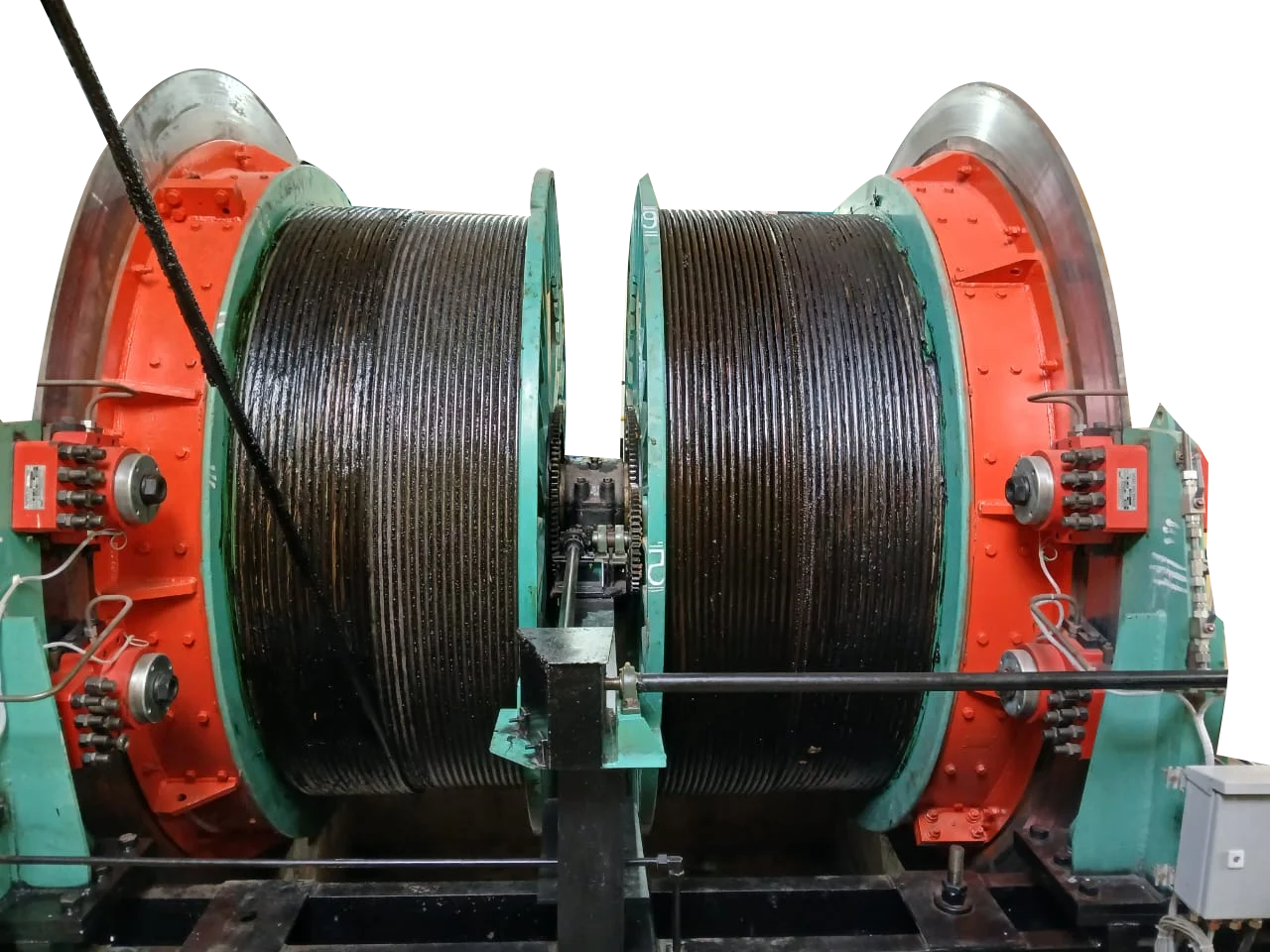

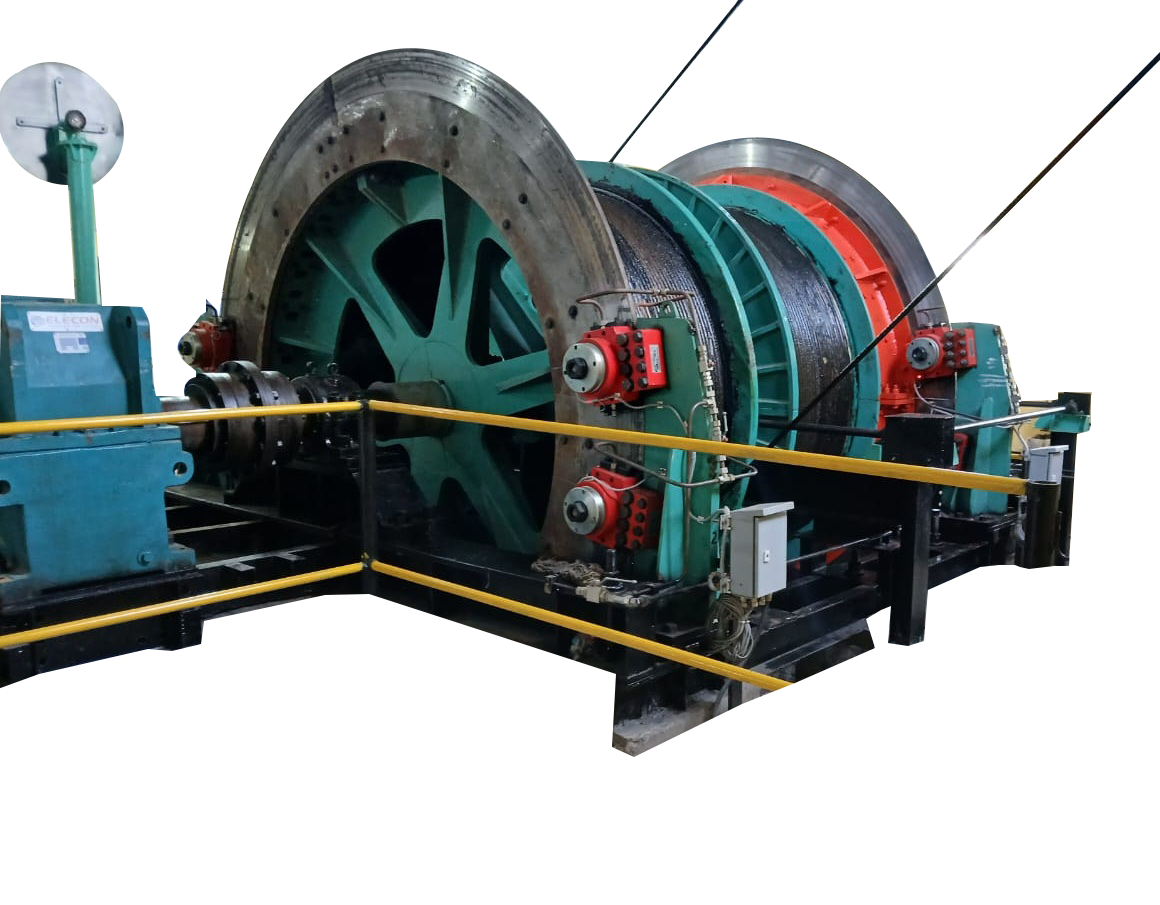

WINDER ENGINES

Winders or Winding Engines are primarily used lower Men and Material from surface to lower levels in all Under Ground Mines. There are two kinds of Winders Single Drum and Double Drum. The manufacture of Winders is an Highly Specialized job and requires lot of safety features, specially when the Winder is being manufactured for Man Winding. The capacity and size of the Winders differ as per the Depth of the Shaft. The speed of Wind will be determined as per the customer requirement. The Winding Engines also used bring out ore through skips. The capacity of the skip and that of its winding engine depends upon the Customer Requirement.

Other Equipments: HEAD GEAR, SKIPS, CAGES, CAGE CATCHERS, MIXING TANKS STORAGE TANKS

Winders or Winding Engines are primarily used lower Men and Material from surface to lower levels in all Under Ground Mines. There are two kinds of Winders Single Drum and Double Drum. The manufacture of Winders is an Highly Specialized job and requires lot of safety features, especially when the Winder is being manufactured for Man Winding. The capacity and size of the Winders differ as per the Depth of the Shaft. The speed of Wind will be determined as per the customer requirement.

Features And Benefits

- This product is designed to deliver exceptional performance across a range of applications.

- High-quality materials ensure durability and long-term reliability.

- Innovative design enhances efficiency and minimizes downtime.

- Compatible with multiple systems for versatile usage.

- Engineered to withstand challenging operating conditions.

- Easy installation process reduces setup time.

- Regular maintenance is straightforward and user-friendly.

- Precision manufacturing ensures consistent output quality.

- Backed by extensive testing for safety and reliability.

- Supported by a comprehensive warranty and customer service.

ELECTRICAL SLIP RINGS

The Electrical Slip Rings are an very critical part of an Sponge Iron Plant and are made from Pure Electrolyte Copper. An minimum purity of 99.96% is maintained in the Rings, The Electrical Slip Rings consists of 4 to 17 Rings depending upon the application. The main purpose of the Rings is to provide uninterrupted power to the shell Air fans mounted on the Rotary Sponge Iron Kilns. The Power is provided through Carbon Brushes which are mounted to Holder made from Brass. The Carbon Brush Holders are fixed on floating Trolleys.

Features And Benefits

- Electrical Slip Rings are a crucial component in sponge iron plants, ensuring efficient operation.

- These rings are crafted from pure electrolyte copper with a minimum purity of 99.96%.

- The number of rings ranges from 7 to 13, depending on the specific application requirements.

- The primary function of the rings is to deliver uninterrupted power to shell air fans mounted on rotary sponge iron kilns.

- Power transmission is achieved through carbon brushes that make consistent contact with the rings.

- The carbon brushes are housed in holders made from durable brass material.

- The brush holders are securely mounted on floating trolleys for optimal positioning and performance.

- The high purity of the copper ensures superior conductivity and reliability during operation.

- The slip rings are designed to handle the rigorous demands of continuous kiln operation.

- These components are engineered for durability, ensuring long-term performance with minimal maintenance.

WET SCRAPPER CONVEYOR

The Wet scrapper Conveyors are large Boat Shaped Equipment used to Convey out Slag/ molten waste etc, flowing out from the Kilns. These are located below DSC (Dust settling chambers) and GCT (Gas Cooling Towers). The Wet Scrapper are filled with water which help in cooling down the hot molten waste and an Chain conveyor inside conveys it out safely. The bottom of the Wet Scrapper is lined with 25 mm Thk CAST BASALT Tiles which increases the longevity of the Mild Steel Casing. The Main Chain is forged from Manganese Steel (MNcr5). The Wet Scrappers are Motorised and speed is reduced and Final RPM of the Chain is 3.8.The Wet Scrapper also consists of safety devices like Shear Pin and Zero Speed Switches.

Features And Benefits

- This product is designed to deliver exceptional performance across a range of applications.

- High-quality materials ensure durability and long-term reliability.

- Innovative design enhances efficiency and minimizes downtime.

- Compatible with multiple systems for versatile usage.

- Engineered to withstand challenging operating conditions.

- Easy installation process reduces setup time.

- Regular maintenance is straightforward and user-friendly.

- Precision manufacturing ensures consistent output quality.

- Backed by extensive testing for safety and reliability.

- Supported by a comprehensive warranty and customer service.

COAL INJECTORS

As the Name suggest the Coal Injectors are used to Inject Coal into the Kiln. These are Motorized and the Capacity vary from 3 TPH to 20 TPH depending upon the capacity of the Plant. The casing of the Coal Injectors is mainly Mild Steel, but the inside is lined with 20mm thk C-45 Plate. It also consists of Rotor made with Stainless Steel 12 mm Thk. Plate. The Coal Injected by compressed Air that flows into the Coal Injector through seamless Pipe.

Features And Benefits

- This product is designed to deliver exceptional performance across a range of applications.

- High-quality materials ensure durability and long-term reliability.

- Innovative design enhances efficiency and minimizes downtime.

- Compatible with multiple systems for versatile usage.

- Engineered to withstand challenging operating conditions.

- Easy installation process reduces setup time.

- Regular maintenance is straightforward and user-friendly.

- Precision manufacturing ensures consistent output quality.

- Backed by extensive testing for safety and reliability.

- Supported by a comprehensive warranty and customer service.

DOUBLE PENDULUM VALVES

The Double Pendulum Valves or D.P.Valves are motorized Cam operated material Handling Equipment The Capacities of D.P.Valves range from 1 TPH to 60 TPH depending upon the production Capacity of the Sponge Iron Plant. These Valves are Intalled at Both Kiln Inlet and Cooler Outlet. The D.P.Valves at Kiln Inlet control the flow of Raw Material into the Kiln intermittently. The inside of these Valves are completely lined with 316 Grade stainless Steel to protect the Mild Steel Body from high heat generated in the Kiln. The top and Bottom Flaps which open and closed alternatively are lined with Hardened Plate like Tiscrol, Sail Hard etc., to protect the Flaps from abrasion. The D.P.Valves at Out Let control the flow of finished product on to the conveyor belt. These D.P.Valves are Air tight and seal false air from entering the system

Features And Benefits

- This product is designed to deliver exceptional performance across a range of applications.

- High-quality materials ensure durability and long-term reliability.

- Innovative design enhances efficiency and minimizes downtime.

- Compatible with multiple systems for versatile usage.

- Engineered to withstand challenging operating conditions.

- Easy installation process reduces setup time.

- Regular maintenance is straightforward and user-friendly.

- Precision manufacturing ensures consistent output quality.

- Backed by extensive testing for safety and reliability.

- Supported by a comprehensive warranty and customer service.

DOUBLE PENDULUM FLAPS

The Double Pendulum flaps or D.P.Flaps are also Motorized CAM Operated Material Handling systems. These are located at Kilns Back Flow Chute to regulate/Collect Dust fines. The D.P.Flaps are all made from Mild Steel and the Flaps are made from stainless Steel 304 Grade Plate. The Capacity Range from 1 TPH to 5 TPH.

Features And Benefits

- This product is designed to deliver exceptional performance across a range of applications.

- High-quality materials ensure durability and long-term reliability.

- Innovative design enhances efficiency and minimizes downtime.

- Compatible with multiple systems for versatile usage.

- Engineered to withstand challenging operating conditions.

- Easy installation process reduces setup time.

- Regular maintenance is straightforward and user-friendly.

- Precision manufacturing ensures consistent output quality.

- Backed by extensive testing for safety and reliability.

- Supported by a comprehensive warranty and customer service.

BUTTERFLY DAMPERS

Butter Fly Dampers are small light weight equipment that are used to regulate and control the flow of Air.

Features And Benefits

- This product is designed to deliver exceptional performance across a range of applications.

- High-quality materials ensure durability and long-term reliability.

- Innovative design enhances efficiency and minimizes downtime.

- Compatible with multiple systems for versatile usage.

- Engineered to withstand challenging operating conditions.

- Easy installation process reduces setup time.

- Regular maintenance is straightforward and user-friendly.

- Precision manufacturing ensures consistent output quality.

- Backed by extensive testing for safety and reliability.

- Supported by a comprehensive warranty and customer service.

SLIDE GATES

These are two types of Side Gates, Pneumatic and Manually operated Slide Gates. These Slide gates ensure the material is regulated by making sure right amount of the material comes out.

Features And Benefits

- This product is designed to deliver exceptional performance across a range of applications.

- High-quality materials ensure durability and long-term reliability.

- Innovative design enhances efficiency and minimizes downtime.

- Compatible with multiple systems for versatile usage.

- Engineered to withstand challenging operating conditions.

- Easy installation process reduces setup time.

- Regular maintenance is straightforward and user-friendly.

- Precision manufacturing ensures consistent output quality.

- Backed by extensive testing for safety and reliability.

- Supported by a comprehensive warranty and customer service.

SCHEDULE AN APPOINTMENT TODAY!

CONNECT WITH US

Let’s Start a Conversation